-

Z Metal

-

Locking W Valley

-

Peak Trim

-

Ridge Cap

-

Sidewall

-

Transition

-

W Valley

-

Ledger

-

J Channel

-

Head End Wall

-

Gable Rake

-

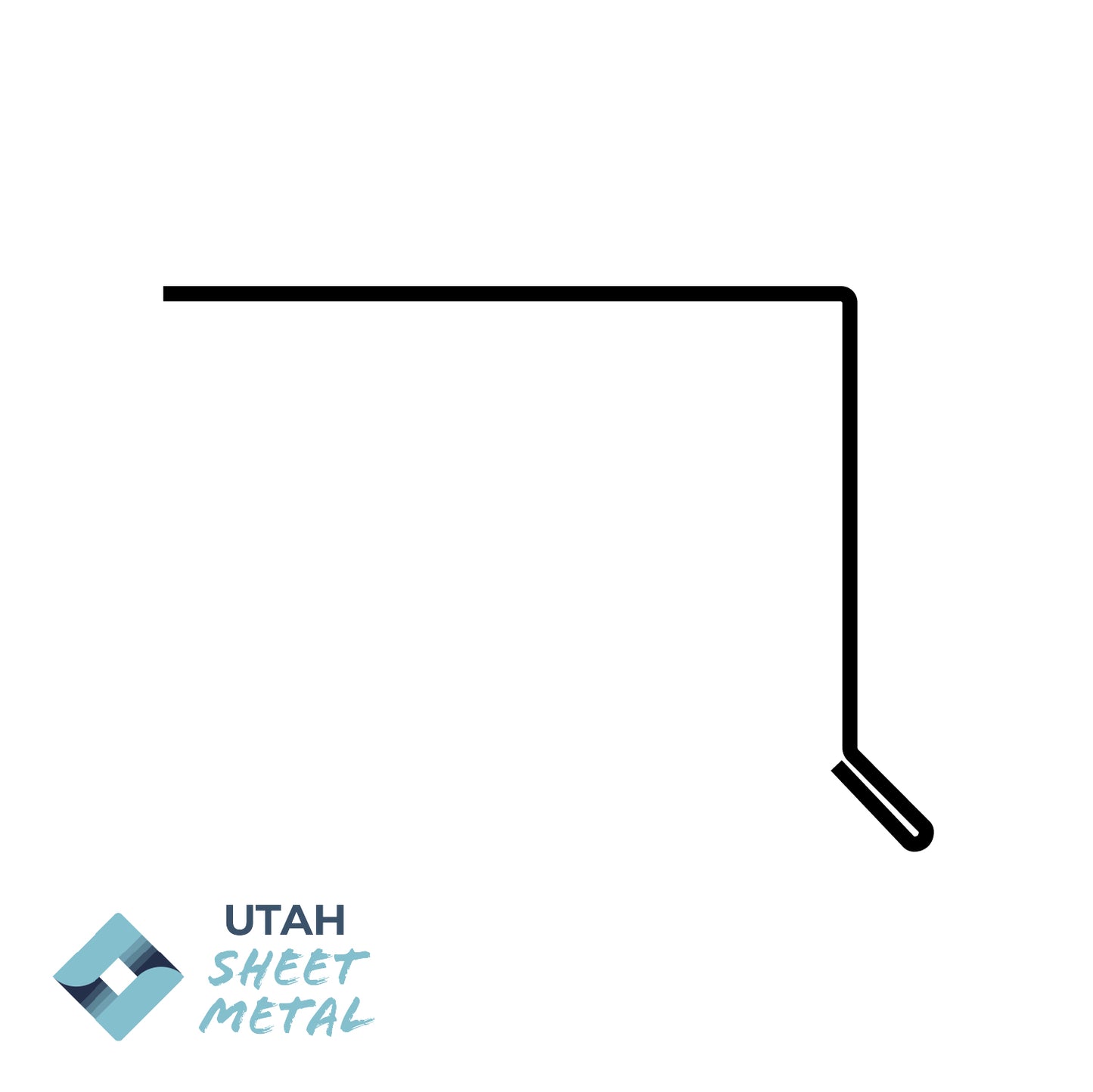

D Style Drip

-

Drip Edge

Flashings

Flashings

Flashings are the custom-formed metal pieces that seal all the gaps and joints on a roof, ensuring water is directed away from critical areas. They might not be as eye-catching as roof panels, but flashings are absolutely vital for a leak-proof roof. We offer a comprehensive selection of standard and custom flashings for any roofing project. Each piece is precision-fabricated in our shop and can be tailored to your needs, whether it’s a typical profile or a unique one-of-a-kind detail.

- Features

- Specifications

- Custom Fabrication: We bend and form flashings to exact specifications so that they fit your project perfectly. From standard pieces to unusually shaped transitions, our skilled fabricators ensure each flashing meets your needs. This custom approach guarantees a better fit and easier installation compared to one-size-fits-all flashings.

- Waterproof Protection: Flashings are strategically installed at roof edges, valleys, ridges, around chimneys/vents, and anywhere the roofing meets another surface. They serve to channel water away from seams and penetrations, preventing leaks. With properly installed flashings, vulnerable areas of your roof stay dry and secure even in heavy storms.

- Quality Materials: We typically use 24-ga pre-finished steel (with a durable paint coating) for most flashings, which offers a great balance of strength and workability. We also offer flashings in copper, aluminum, or stainless steel for specialty applications or aesthetic preference. All materials are high-quality and suitable for long-term exterior use.

- Wide Range of Profiles: Our catalog of flashings includes all the common profiles you’d expect – for example, drip edge, gable rake trim, valley flashing, W-valley, step flashing, headwall and sidewall flashings, ridge caps, Z-metal, J-channel, and more. We can also create any custom profile required. If you have a complex roof geometry or a unique detail, we will fabricate a flashing solution to handle it.

- Matching Finish: Flashings can be made to match your roofing panels in color and finish for a seamless look. We use matching color-coated metal (or complementing metals like mill-finish copper) so that the flashings blend in with the roof design rather than standing out. The result is both functional and aesthetically pleasing.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Name 1

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Name 2

- Standard Length: 10 feet (120 inches) is the standard length for most flashing pieces, which allows for manageable installation and transportation. Pieces are overlapped or seamed during install to cover longer runs. (Custom longer lengths up to ~21 feet may be available by special request for certain profiles.)

- Material Thickness: 24-gauge steel is our standard for roof flashings, providing durability and resistance to bending or oil-canning. Some profiles can also be made in 26-ga (slightly thinner) or 22-ga (thicker) if needed. For copper or zinc, typical thickness would be 16 oz copper or equivalent.

- Metal Options: Painted galvanized steel (Galvalume) in 24-ga with factory color finish is most common. Also available in mill-finish or patina copper, stainless steel, Galvalume®, aluminum, and zinc. We work with virtually any sheet metal the project demands.

- Installation: Flashings are secured with appropriate fasteners and lapped or soldered (for copper) to ensure continuity. We recommend using sealant or butyl tape between overlaps for added waterproofing, especially in critical areas. Our flashings are designed to integrate with roofing panels and prevent water intrusion even in wind-driven rain.

- Custom Profiles: If you have architectural drawings or existing conditions, we will fabricate flashings to those exact profiles. Simply provide the dimensions or a template – we can make anything you need when it comes to sheet metal flashings.

PROJECTS

Over the years, we have fabricated hundreds of custom flashings for roofs of all shapes and sizes. In the gallery below, you can see examples of our flashings in use – from ornate copper turret flashings to standard eave and valley treatments on homes. These project photos highlight how proper flashings contribute to a clean finish on the roof and, more importantly, a dry structure. Feel free to explore the gallery to get a sense of the craftsmanship and variety in our flashing work.

Frequently Asked Questions

What exactly are roof flashings, and why do I need them?

Flashings are pieces of sheet metal that are installed at critical areas of the roof (joints, edges, penetrations) to prevent water from seeping in. Think of them as protective covers for gaps or transitions on the roof. Without flashings, water could leak into the roof at corners, valleys, around chimneys, vents, skylights, and where the roof meets walls. Quality flashings are absolutely essential for a water-tight roof – they direct rain and melting snow away from vulnerable areas, guarding your home against leaks and water damage.

Do you fabricate custom flashings for unique situations?

Yes – all the time. In fact, custom fabrication is our specialty. We can make flashings for any situation: odd angles, curves, non-standard transitions, you name it. In addition to standard pieces (like drip edges, ridge caps, etc.), we will gladly fabricate one-off flashing profiles as needed to ensure your roof is completely protected. Our shop uses precision press brakes and shears, enabling us to create flashings to exact dimensions and profiles that you or your architect specify. If you have a tricky area on your roof, we’ll design and build a flashing that fits it perfectly.

What materials can flashings be made from?

We offer flashings in a variety of metals. Most commonly, we use 24-gauge galvanized steel with a factory color finish (to match your roof panels). This material is durable, long-lasting, and matches the panel color exactly. However, we can also make flashings out of stainless steel, aluminum, or copper if required. For example, if you have a copper roof or accents, we’d fabricate copper flashings to match. All materials we use are high quality, rust-resistant, and appropriate for their intended application.

How are flashings installed? Do I need special tools?

Flashings are typically installed by the roofing contractor as part of the roof installation. They are placed under or over the roofing material at transitions (depending on the type). For example, a drip edge flashing goes under the shingles/metal at the roof edge but over the fascia. Most flashings are nailed or screwed into place using corrosion-resistant fasteners. In some cases (like certain copper flashings), pieces may be soldered at the seams for a seamless finish. While no especially exotic tools are needed (basic hand tools and a metal snip for adjustments), proper technique is important – so we recommend installation by an experienced roofer or sheet metal worker. We supply the custom-made flashings; your installer will ensure they’re fitted and sealed correctly on your roof.

Can I buy standard flashing pieces from you, or do you only do custom?

You can absolutely get standard flashing pieces from us. We commonly fabricate standard profiles such as eave drip, valley flashing, ridge caps, step flashing, etc., in the sizes used for most roofs. These are made-to-order in the length and color you need (standard is 10’ length). The advantage of getting them from us is that even our “standard” pieces are made specifically to match your project (for example, to the exact panel profile or roof pitch you have). So you get the convenience of a standard shape, but with a custom fit and finish. If you’re a contractor in need of common flashings in bulk, we can turn those around quickly. And if you need something unusual, we’re ready to make that too.